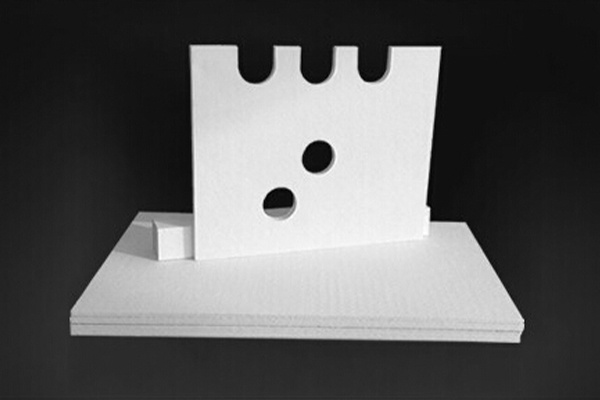

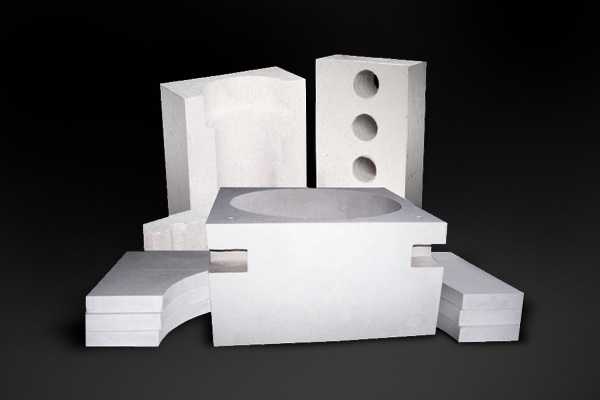

Ceramic fiber shaped parts

Ceramic fiber special-shaped parts are made of high-quality ceramic fiber cotton as raw material and are made by vacuum forming process. The purpose of developing this product is to produce rigid and self-supporting shaped products with superior high temperature performance.

Key words:

Category:

Product Description

Product Description:

◎Ceramic fiber special-shaped parts are made of high-quality ceramic fiber cotton as raw material, and are made by vacuum forming process. The purpose of developing this product is to produce rigid and self-supporting shaped products with superior high temperature performance.

◎Ceramic fiber special-shaped parts are all special-shaped products that meet the specific production links of some industrial sectors. Each product needs to make a special mold according to its shape and size. According to the performance requirements of the product, use different binders and additives. meet the usage requirements.

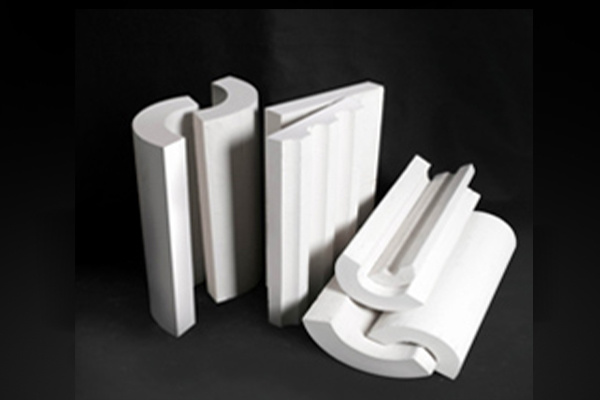

◎All special-shaped products have low shrinkage in their operating temperature range, and maintain the characteristics of high heat insulation, light weight and impact resistance.

◎Unscorched material can be easily cut or machined. During use, the product resists wear and spalling well and is not wetted by most molten metals.

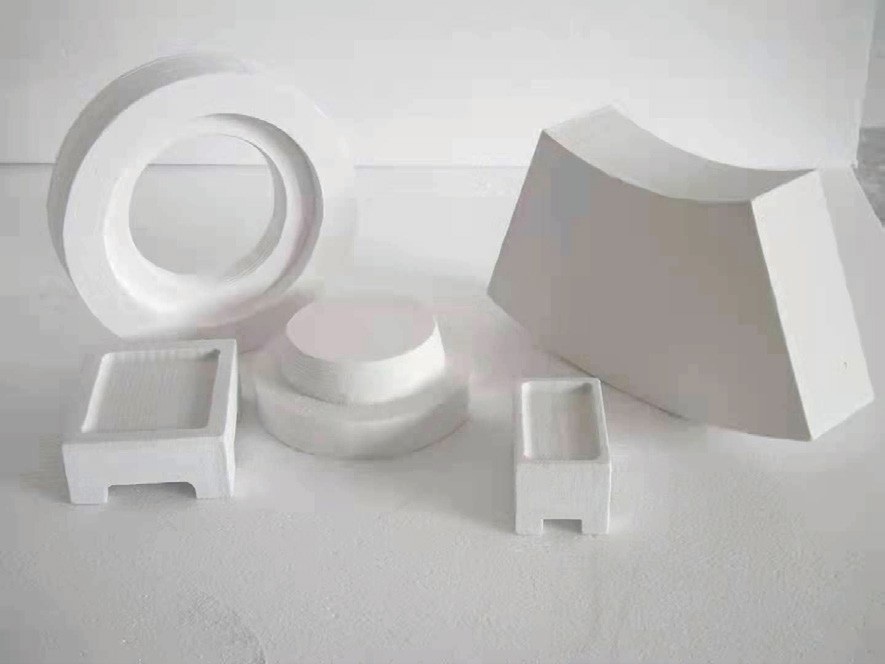

◎Shape and Availability: Vacuum-formed special-shaped products can have various sizes and shapes, including tube, cone, dome and square box. Most special-shaped products can be produced according to customer requirements, but some special-shaped products We can also make inventory for customers, such as casting caps and casings for the non-ferrous metal industry, and vacuum forming fire holes for the petrochemical industry.

◎General characteristics: The physical and thermal properties of various special-shaped products are generally similar to those of the corresponding grades of vacuum formed sheets.

◎Special treatment: If necessary, vacuum forming hardener or refractory mud can be applied on special-shaped products to provide a protective layer.

|

Product Category:

Features: |

Typical application: ◎Industrial furnace observation hole, thermometer temperature measurement hole ◎Industrial kiln burning nozzle brick ◎Industrial furnace door ◎Sump and launder in the aluminum products industry ◎Heat radiation blocks for civil and industrial heating installations |

|

Technical indicators :

|

Product name |

Ceramic fiber shaped parts |

||||

|

Classified temperature |

1260 |

1400 | |||

|

Product Code |

HZGX-255 |

HZGX-355 | HZGX-455 | HZGX-555 | HZGX-755 |

|

Heating permanent line change (%) |

1000℃ ×24h |

1100℃ ×24h ≤ -3 |

1200℃ ×24h ≤ -3 |

1350℃ ×24h ≤ -3 |

1400℃ ×24h ≤ -3 |

|

Theoretical Thermal Conductivity |

Average 200°C |

0.055-0.065 | 0.060-0.070 | ||

|

Average 400°C |

0.110-0.120 | 0.115-0.125 | |||

|

Average 600°C |

0.160-0.170 | 0.170-0.180 | |||

|

Moisture content (%) |

≤ 1 |

||||

|

Compressive strength (10% compression in thickness direction) |

≥ 0.2 |

||||

|

AL2O3(%) |

|

50-60 | |||

|

Density (kg/m3) |

300-400 |

||||

|

Product Specifications (mm) |

According to customer drawings |

||||

|

Packaging |

Inner plastic bag outer carton |

||||

Related Products

Product message

Mobile official website

Shandong Hengze Energy Saving Technology Co., Ltd.

Address: Room 1304, Building 2, Phoenix SOHO International Plaza, Fenghuang Road, High-tech Zone, Jinan City, Shandong Province

Tel/Fax: +86-0531-83249209

Tel: +86-18678770869

Email: 18364373399@163.com

Web:

copyright © 2022 Shandong Hengze Energy Saving Technology Co., Ltd.